CO2 laser machines are ideal for processing textiles. Both natural and synthetic fabrics can be cut and engraved with lasers. Polyester, nylon, cotton, felt, woven, non-woven and glass fiber fabrics, as well as heat resistant and other technical textiles have been used for laser cutting.

Detailed graphics and intricate designs are now possible with laser engraving and cutting which was otherwise not possible with traditional methods.

The thermal laser process ensures the cutting edges are automatically sealed when cutting textiles, therefore ensuring no rough edges or fraying during the process. The non-contact laser processing, deformation-free cutting and high precision are also highlighted advantages for using laser technology in textiles processing.

CO2 laser cutting machines can work on any type of textiles. There is a list of common fabrics and textiles that would work well with laser cutting technology:

What types of textiles are ideal for laser processing?

What are the benefits of laser cutting and engraving of textiles?

Laser processing available on textiles and fabrics

With laser technology, cutting, marking and engraving can be performed in a very fast and repeatable way, saving time and reducing costs. As a result, laser solutions have higher productivity and flexibility.

The main advantages of using lasers in the textile sector are:

Clean and perfect cutting edges

Textile finishing by laser engraving

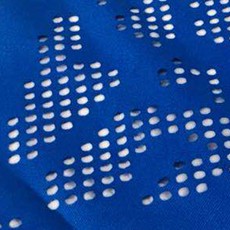

Capable of laser cutting small holes

- No fraying, or post-processing will be required

- Textiles are processed without distortion

- Possibility to carry out complex drawings

- The laser beam is unaffected by wearing from material processing

Highlights of Golden Laser’s CO2 laser machines for textiles and fabrics processing:

Gear and rack drive

High speed and acceleration, and can maintain long-term stability

High precision

Spot size up to 0.1mm. Perfectly handling angles, holes, and complex graphics

Conveyor system

For the fully automated laser processing directly from the roll

Automatic roll feeder

With tension correction function, ensuring continuous and accurate feeding

Automatic nesting

Maximizing material utilization thanks to nesting software

Marking function

Inkjet printer module and Ink marker module are available.

Multiple power options

Various CO2 laser powers from 65 watts to 800 watts are available

Variety of table sizes

Working table formats can be customized, even ultra long and wide table size

Laser heads

Double laser heads or multiple laser heads are available for productivity improvement

Camera recognition systems

For the laser cutting of printed fabrics or embroidered labels

Automatic sorting system

Automatic laser intelligent manufacturing solution for Industry 4.0

Typical applications for processing textiles with CO2 laser machines from Goldenlaser

Filters - filter cloth, filter mat, filter material - laser cutting PP, PA, polyester, nylon fabric and fiberglass media

Insulation Materials - heat protection fabrics, thermal insulation fabrics, woven heat shrinking protection sleeve laser cutting

Air Dispersion Ducts - fabric air duct (air socks, soxduct) laser cutting and perforation

Automotive & Aviation

1) Airbags - laser cutting automobile airbags

2) Interior upholstery - laser cutting car seat covers, car mats and sunshades

3) Thermoelectrically heat car seat - laser cutting car seat heater

4) Aircraft carpet laser cutting

Outdoors & Sporting Goods - tents, sails, parachutes shading fabrics laser cutting; Marine mat laser engraving (marking)

Active Wear & Sportswear - Contour cutting of sublimation prints; Laser perforation of apparel fabric; Precise cutting lettering, numbering on uniforms…

Upholstery - curtains, sofas, cushion materials, pillows, floor and wall coverings, furnishing fabrics laser cutting and engraving

Clothing Industry

- Made to measure, ready-to-wear, haute couture - fabrics laser cutting, engraving and perforating

- Applique, embroidered badges, patches, labels, woven labels laser cutting

Textile printing - laser cutting printed polyester fabrics of banners, flags, soft signage

We have developed specific laser machines for the textile sector. Choose the product that best fits your needs, and contact us for advice.

Flatbed Laser Cutting Machine

CO2 laser cutter for large-format industrial fabrics.

Work area (Width): 1600mm ~ 3200mm (63” ~ 126”)

Work area (Length): 1300mm ~ 13000mm (51” ~ 511.8”)

Gantry & Galvo Integrated Laser Cutting and Marking Machine

Cutting, engraving, perforating and kiss-cutting with high speed on one machine for format up to 1.7m × 2m (66.9" × 78.7")

Vision Scanning Laser Cutting Machine for Sublimation Fabric

Automatic and digital cutting solutions for dye-sublimation printed fabrics and textiles from a roll of nested printed shapes.