Cross car beams are complex parts, which make a decisive contribution to the stability and safety of every vehicle in which they are used. As a single cross strut in the vehicle interior they ensure that, in the event of a side impact, the passenger compartment is not compressed. Cross car beams also hold the steering wheel, the airbags, and the entire dashboard. Depending on the model, we can manufacture this crucial part in steel or aluminum.

Hyundai Motor Company is a famous motor company in Korea, who is committed to becoming a lifetime partner in automobiles and beyond. The company - which leads the Hyundai Motor Group, is an innovative business structure capable of circulating resources from molten iron to finished cars. To improve their production efficiency and upgrade their equipment, the company decided to introduce pipe laser cutting machine.

Customer requirements

1. The customer's product is pipe for automotive industry, and its need massive and automatic processing.

2. Pipe diameter is 25A-75A

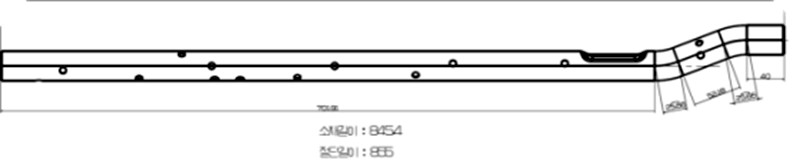

3. The finished pipe length is 1.5m

4. The semifinished pipe length is 8m

5. After laser cutting, it requests that the robot arm can directly grab the finished pipe for follow-up bending and press processing;

6. Customer has requirements for laser cutting accuracy and efficiency, and the maximum processing speed is not less than 100 R/M;

7. The cutting section should have no burr

8. The cut circle should close to perfect circle

Our solutions

After carefully study, we set up a special research group including the R&D department and our production manager to figure out a solution for their requirements.

Pipe Laser Cutting Machine P2080A

On the base of P2060A we customized one model P2080A pipe laser cutting machine to meet their requirements of cutting 8 meters length pipe and the automatic loading.

On the end of material collecting, it added one robot arm for pipe grabbing. To ensure the cutting precision, every single piece should be clamped tightly by robot arm before cutting.

After cutting, the robot arm will deliver the pipe to later procedures for press and bending. The holes of the bend pipe should be cut by the 3D robot laser cutting machine.