The digital printing revolution has changed the landscape of label creation significantly.

With the flexibility of printed design, the need to easily change the cut shape to match has become very important. Traditionally, cutting has been done with mechanical die presses and knife slitters, where the user is locked into one design for a production shift. The cost and complex logistics of storing multiple dies make it unfeasible to have many cut shapes available.

Furthermore, downtime associated with tooling changes reduces productivity metrics, which is often a deciding factor in overall cost of operations. Laser cutting with high-speed scan heads has changed this to a dynamic and easily flexible process, where cut design changes can be done on the fly via software without stopping the production line. The digital printing revolution is ushering in need for laser processing because it is an ideal technology to produce short-run, custom jobs.

The advantages of laser-based converting are numerous.

In addition to the digital flexibility of new design that can be changed on the fly, other benefits such as yield improvements derived from a non-contact method must not be overlooked, particularly as labels get thinner and with the selective capability to "kiss-cut" into a controlled depth. Also, laser-based processing has no consumables (i.e., no worn-out mechanical tools) and offers repeatable results (lasers do not get dull). For these reasons, the performance advantages offered by laser-based, digital, non-contact technology are compelling.

Real modular system with more available converting options

IT IS TIME TO MOVE YOUR LABEL BUSINESS FORWARD!

Lamination / UV Varnishing / Cold Foil / Laser Cutting / Perforating / Etching / Scoring / Hot Stamping / Flat Bed Die Cutting / Semi Rotary Die Cutting / Waste Rewind / Slitting ...

What are the benefits of Goldenlaser’s laser die cutting machine for labels finishing?

DIGITAL LASER CUTTING SOLUTIONS FOR LABELS

Application Fields

Goldenlaser’s laser converting systems have provided our clients with opportunities in new and existing markets, such as:

Product Recommendation

Goldenlaser has developed specific label laser cutting systems for the labeling and packaging sector. Choose the product that best fits your needs, and contact us for advice.

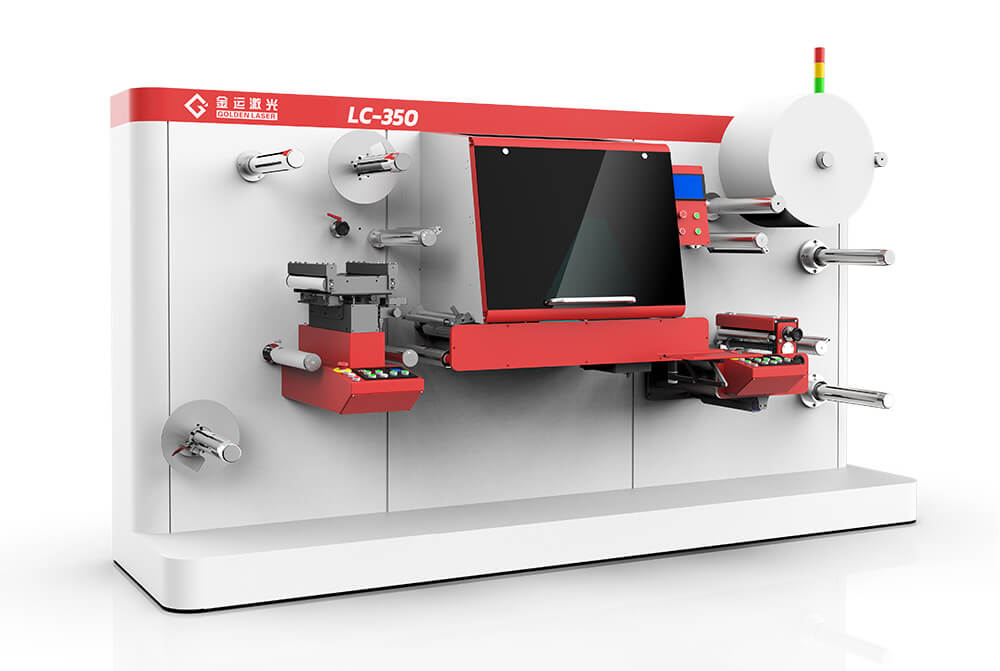

LC350 Digital finishing with single or dual laser cutting head

The laser cutting machine has the flexibility to be customized with different converting options to enhance your products and provide efficiency to your production line.

Standard configuration

- • BST Web Guide

- • Single Source Scan Head

- • Waste Removal

- • Unwind

Optional configuration

- • Double Source Scan Head

- • Bar Code Reading

| Model No. | LC350 |

| Laser power | 150W, 300W, 600W |

| Maximum cutting width | 340mm |

| Maximum web width | 350mm |

| Maximum web diameter | 750mm |

| Web speed | ≥80m/min |