Features of the Fiber Laser Cutting Machine

Full protection design

Enclosed work space makes your cutting process safer!

High-definition camera monitor

Fully enclosed design ensures safe observation of the cutting process. It is equipped with a high-definition camera to monitor the cutting process in real time.

Double exchange sheet handling system

In-line pallet changer, exchange fast, saving loading time.

1.5m×3m (5’×10’), 1.5m×4m (5’×13’), 1.5m×6m (5’×20’), 2m×4m (6.5’×13’), 2m×6m (6.5’×20’), 2.5m×6m (8.2’×20’) working table sizes available.

One Machine - Dual Use

Process both tube and flat sheet in a single machine.

It is a combination machine which combines a flat sheet cutter along with a tube spindle for processing tubular shapes. The combination machine is an excellent choice for fabricators with both flat sheet and tube cutting requirements that don’t have the volume to justify buying two separate machines.

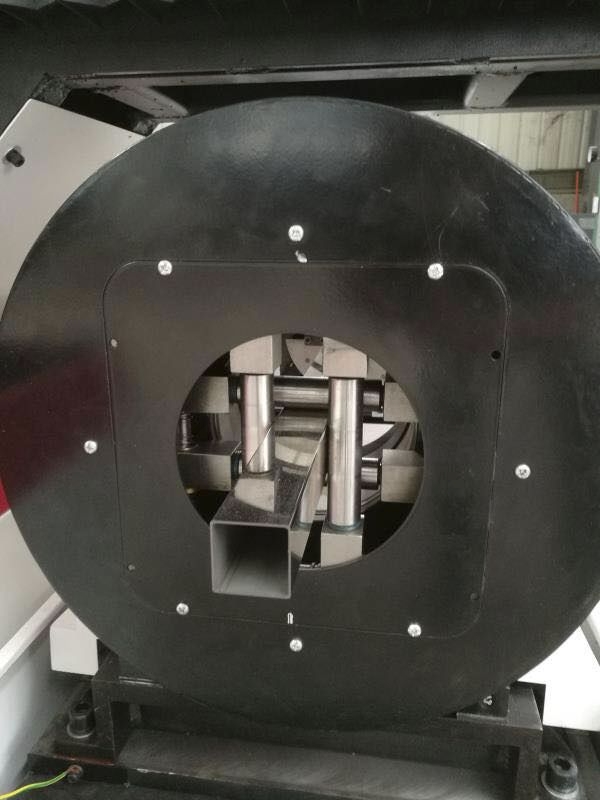

Automatic chuck for tube clamping

The chuck automatically adjusts the clamping force according to the tube type, diameter and wall thickness.

The thin-walled tube does not deform and the large tube can be clamped tightly.

Fast speed, cutting speed is up to 90m/min

Rotating speed 180R/min

Gantry double drive structure, high damping bed, good rigidity, high speed and acceleration.

Drawer-type collection trays facilitate collection and cleaning of scraps and small parts.

The world-class fiber laser source and components ensure superior stability of the machine.

Features of the Fiber Laser Cutting Machine

| Models |

GF-1530JHT / GF-1540JHT / GF-1560JHT / GF-2040JHT / GF-2060JHT |

| Sheet processing |

1.5m×3m, 1.5m×4m, 1.5m×6m, 2m×4m, 2m×6m |

| Tube processing |

Tube length 3m,4m, 6m; tube diameter 20-200mm |

| Laser source |

nLight / IPG / Raycus fiber laser resonator |

| Laser source power |

1000W / 1500W / 2000W / 2500W / 3000W / 4000W |

| Positioning accuracy |

±0.03mm/m |

| Repeat positioning accuracy |

±0.02mm |

| Maximum positioning speed |

120m/min |

| Acceleration |

1.5g |

| Cutting speed |

Depend on material, laser source power |

| Electric power supply |

AC380V 50/60Hz |

Application of the Fiber Laser Flat Sheet and Tube Cutting Machine

Applicable metal material

Carbon steel, stainless steel, galvanized steel, iron, alloy, aluminum, brass, copper, titanium, etc.

Applicable tube type

Round tube, square tube, rectangular tube, oval tube, waist round tube, etc.

Applicable Industry

Metal fabrication, hardware, kitchenware, electronics, automotive parts, glasses, advertising signs, lighting, decoration, jewelry, furniture, medical device, fitness equipment, oil exploration, display shelf, agriculture and forestry machinery, bridges, ships, structure parts, etc.