What are the advantages of automotive airbags cutting with laser?

Save labor

Multi-layer cutting, cutting 10-20 layers at a time, saving 80% of labor compared to single-layer cutting

Shorten the process

Digital operation, no need for tool construction or changeover. After laser cutting, the cut pieces can be directly used for sewing without any post-processing.

High quality, high yield

Laser cutting is thermal cutting, resulting in automatic sealing of the cutting edges. Moreover, laser cutting is high precision and it is not limited by graphics, the yield is as high as 99.8%.

High efficiency, high productivity

Integrating the world's advanced technology and standardized production, the laser cutting machine is safe, stable and reliable. The daily output of a machine is 1200 sets. (Calculated by processing 8 hours per day)

Safe, environmentally friendly and low operating costs

The core components are maintenance-free, require no additional consumables, and cost only about 6 kWh per hour.

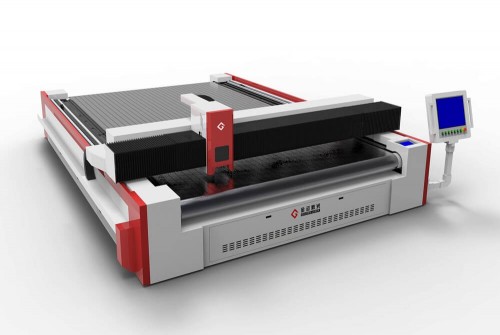

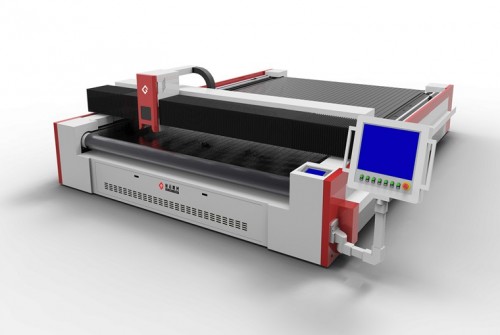

Technical Specifications of the Cutting Laser Machine

| Laser source | CO2 RF laser |

| Laser power | 150 watt / 300 watt / 600 watt / 800 watt |

| Cutting area (W×L) | 2300mm×2300mm / 3000mm×3000mm (90.5” ×90.5” / 118”×118”) |

| Cutting table | Vacuum conveyor working table |

| Cutting speed | 0-1200mm/s |

| Acceleration | 8000mm/s2 |

| Repeating location | ≤0.05mm |

| Motion system | Offline mode servo motor motion system, High precision gear rack driving |

| Power supply | AC220V±5% / 50Hz |

| Format support | AI, BMP, PLT, DXF, DST |

| Optional | Auto-feeding system, red light positioning, Mark pen, ink-jet marking device |

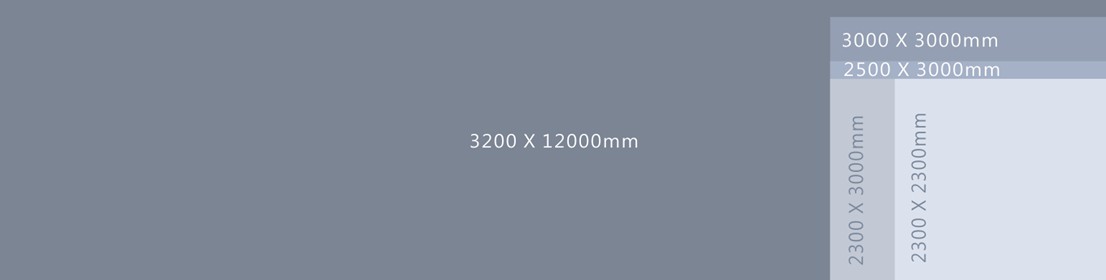

Working areas can be customized

1600mm×3000mm (63”×118”), 2300mm×2300mm (90.5”×90.5”), 2100mm×3000mm (82.6”118”), 2500mm×3000mm (98.4”×118”), 3000mm×3000mm (118”×118”), 3500mm×4000mm (137.7” ×157.4”) Or other options.

Automotive airbags laser cutting sample