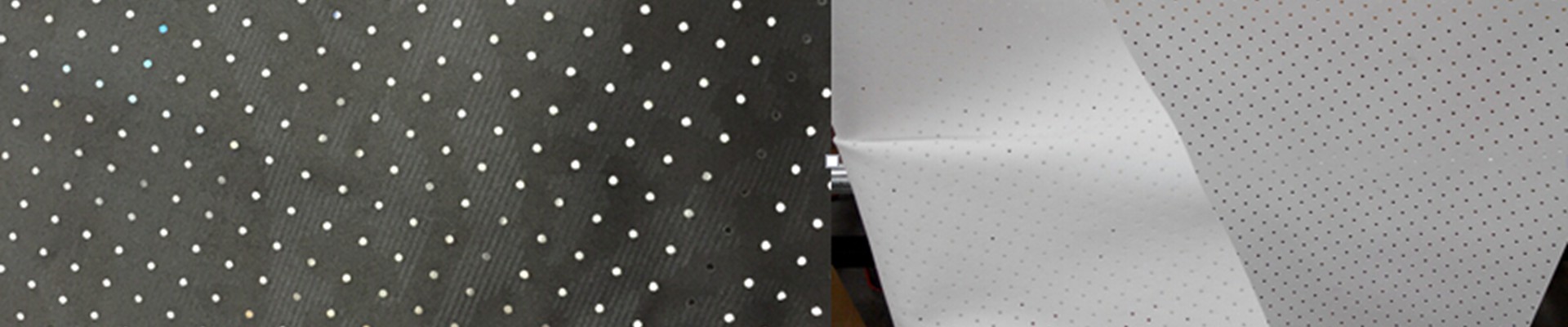

There are two different ways to make sportswear with breathability. One typical method is to use a sportswear fabric that already has breathable holes. These holes are made during knitting, which we call "mesh fabrics". The main component of the fabric is cotton, which contains a low-component polyester, which is not very effective in breathability and moisture wicking.

Another typical fabric that widely used is dry fit mesh fabrics. This is normally for standard level sportswear application.

However, for the high-end sportswear, the materials are usually high polyester, spandex with high tension, high elasticity. These functional fabrics are very expensive and are widely used in athletes' jerseys, fashion designs, and high value-added clothing.

The breathable holes of the jerseys are generally designed in some specific positions, such as underarms, back, and shorts. Special fashion designs of breathing holes are also widely used for activewear.

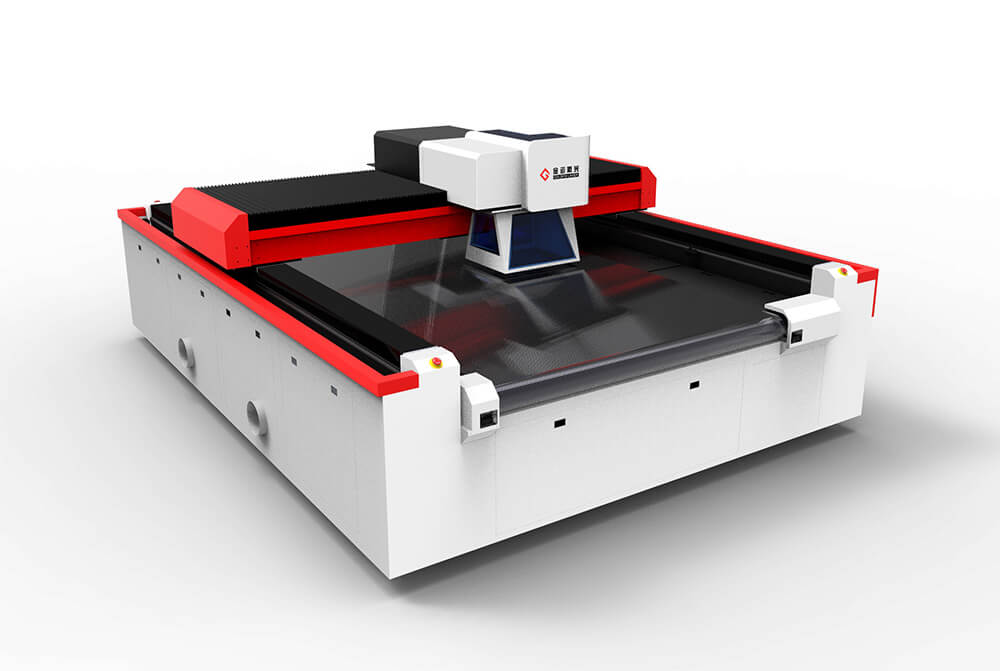

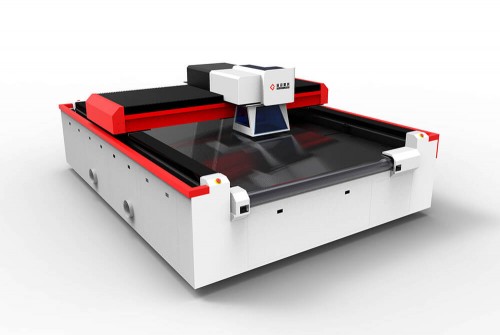

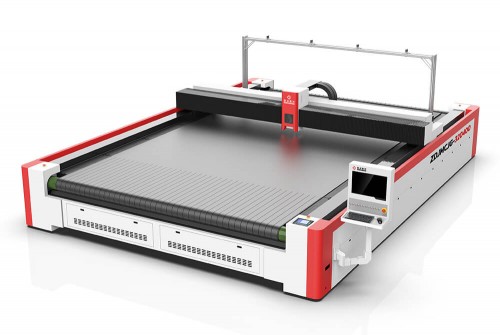

For this industry, Goldenlaser developed a high-speed perforating and cutting laser machine for sportswear fabrics.

Machine Features

Process: Cutting, Engraving, Marking, Perforation, Scoring, Kiss Cutting

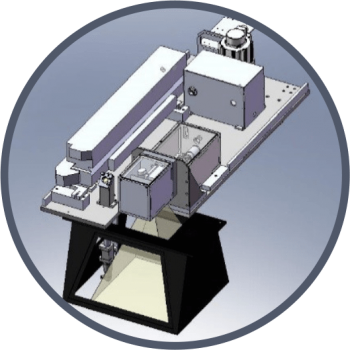

This laser machine combines galvanometer and X-Y gantry, sharing one laser tube. The galvanometer offers high speed engraving, perforating and marking, while X-Y Gantry allows laser cutting patterns after Galvo laser processing.

Conveyor vacuum working table is suitable for the materials both in roll and in sheet. For roll materials, an auto feeder can be equipped for automatic continuous machining.

Technical specifications of the laser cutting machine

| Working Area | 1700mm × 2000mm / 66.9" × 78.7" |

| Working Table | Conveyor working table |

| Laser Power | 150W / 300W |

| Laser Tube | CO2 RF metal laser tube |

| Cutting System | X-Y Gantry cutting |

| Perforation / Marking System | Galvo system |

| X-Axis Drive System | Gear and rack drive system |

| Y-Axis Drive System | Gear and rack drive system |

| Cooling System | Constant temperature water chiller |

| Exhaust System | 3KW exhaust fan × 2, 550W exhaust fan × 1 |

| Power Supply | Depends on laser power |

| Power Consumption | Depends on laser power |

| Electrical Standard | CE / FDA / CSA |

| Software | GOLDEN LASER Galvo software |

| Space Occupation | 3993mm(L) × 3550mm(W) × 1600mm(H) / 13.1’ × 11.6’ × 5.2’ |

| Other Options | Auto feeder, red dot positioning |