LC8060 Sheet Fed Laser Cutter features continuous sheet feeding, laser cutting on-the-fly and automatic collection working mode. The steel conveyor moves the sheet continuously to the appropriate position under the laser beam with no stop or start delay between sheets. LC8060 is ideal for sheet label cutting and other jobs requiring die cutting, kiss cutting as well as creasing. Eliminating the time and cost of making dies, it is ideally suited to short-run labels, custom shaped cards, prototypes, packaging, carton and other projects that would normally require more expensive mechanical dies.

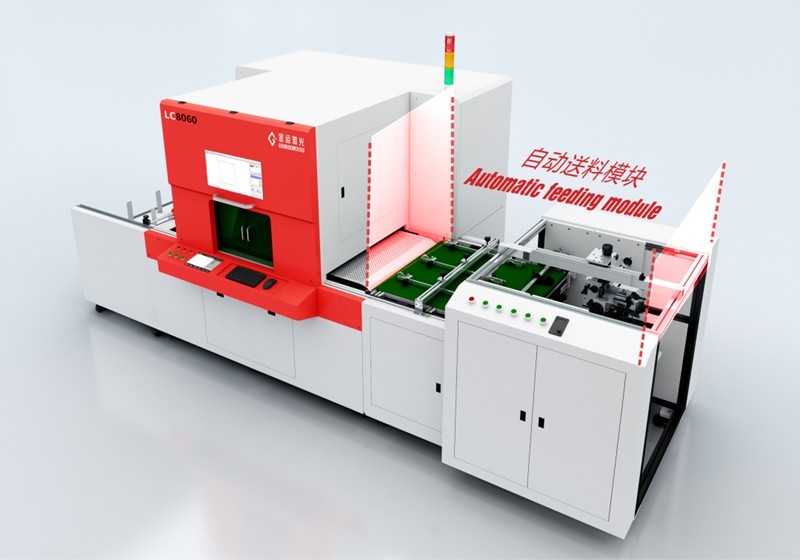

Automatic Feeding Unit

Automatic loading, with liftable platform function, reliable movement and smooth transmission, ensuring continuity and stability of feeding.

Laser Cutting Unit

Self-developed special vision software with high-definition industrial cameras to read barcodes for jobs changeover.

Single, dual or multi-head lasers can be selected according to processing efficiency requirements and material characteristics. The type and power of the laser can be customized and selected on demand.

Technical Parameters

|

Model |

LC8060 |

|

Design type |

Sheet fed |

|

Max cutting width |

800mm |

|

Max cutting length |

800mm |

|

Accuracy |

±0.1mm |

|

Laser type |

CO2 laser |

|

Laser power |

150W / 300W / 600W |

|

Dimensions |

L4470 x W2100 x H1950(mm) |