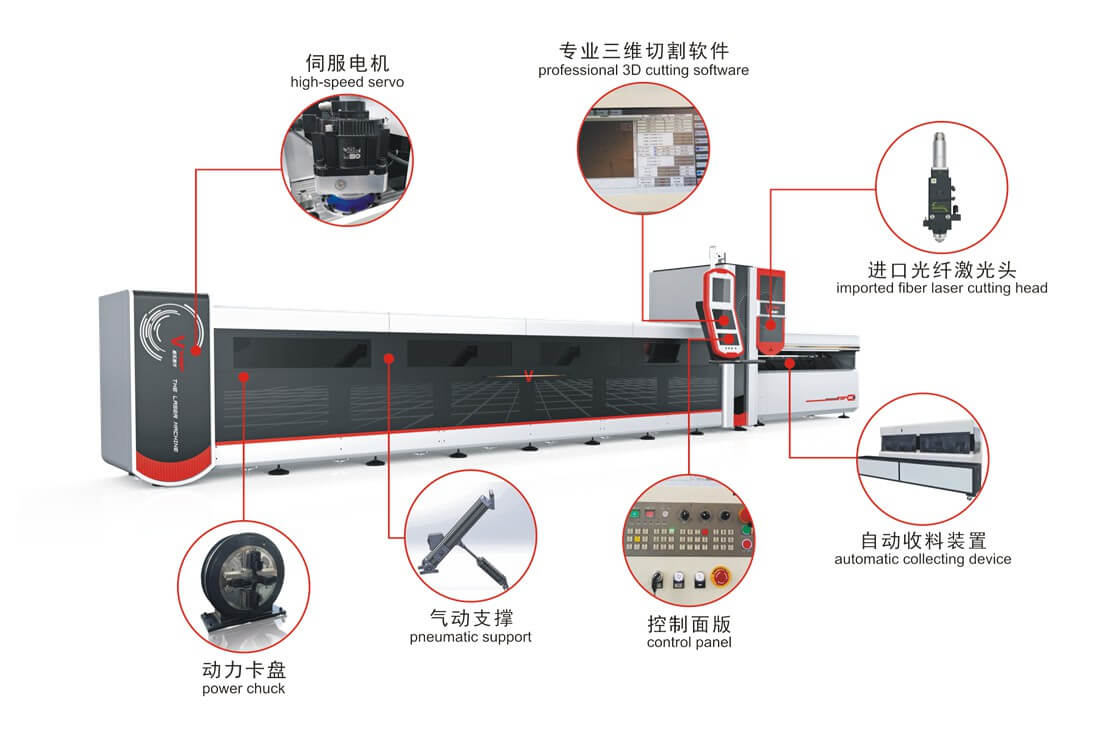

Main Parts of Laser Tube Cutting Machine

Advanced chuck clamping system

• Chuck center self-adjustment, automatically adjusts the clamping force according to the tube profile specifications and ensures no damage to thin pipe.

• Dual motive chucks are compatible with a variety of pipe without adjusting jaws.

• Long stroke clamp. No need to adjust the clamp when the pipe diameter changes within 100mm

Corner fast cutting system

Corner fast response, improves cutting efficiency greatly.

Multi-axis linkage

Multi-axis (feeding axis, chuck rotation axis and the laser cutting head) linkage when the laser cutting head is moving.

Automatic collecting device

• The floating support device collects the finished pipes automatically.

• The floating support is controlled by the servo motor and it can adjust the support point according to the pipe diameter quickly.

• The floating panel support can hold the large diameter pipe tightly.

Automatic Floating Support

According to the change of the pipe attitude, the support height can be automatically adjusted in real time to ensure that the bottom of the pipe is always inseparable from the top of the support shaft, which plays the role of dynamically supporting the pipe.

Welding seam recognition

The welding seam position of the pipe can be identified to ensure that the cutting position avoids the welding seam during processing and avoid the problem of blasting holes at the welding seam.

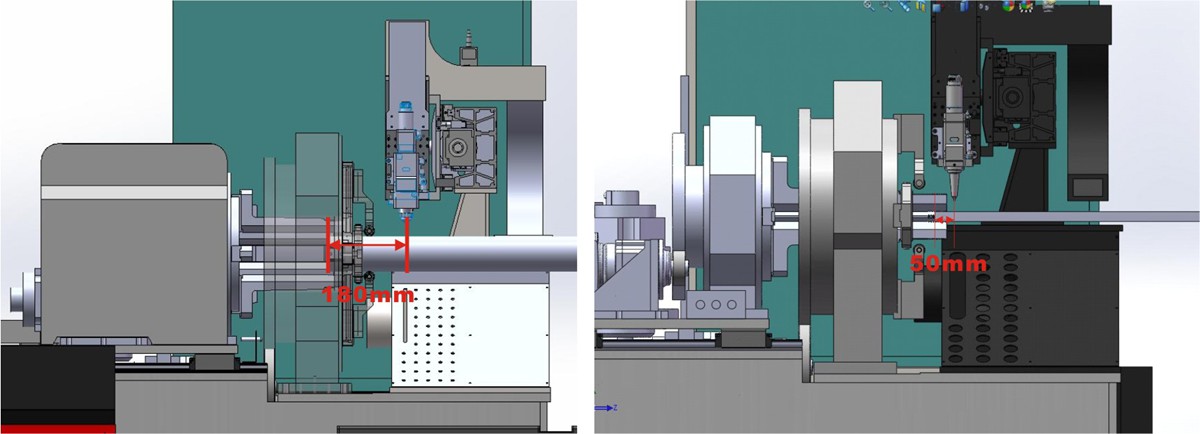

“Zero” Wastage

When cutting to the last part of the tube, the front chuck jaws are automatically opened, and the rear chuck jaws pass through the front chuck to reduce the cutting blind area.

• Tube diameter less than 100 mm, wastage materials 50-80 mm

• Tube diameter more than 100 mm, wastage materials 180-200 mm

Optional - the third axis cleaning inner wall device

During the laser cutting process, the slag will inevitably adhere to a part of the inner wall of the opposite pipe. In particular, some pipes with smaller diameters will have more slag. For high demand applications, the third axis cleaning inner wall device can be added to prevent slag adhering to the inner wall.

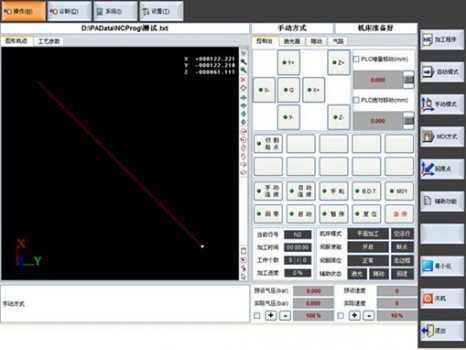

German PA control software

- • One page completes all operations more user-friendly!

- • Quickly customize the interface, more convenient!

- • Add an independent diagnosis interface to quickly troubleshoot on-site problems, more intelligent!

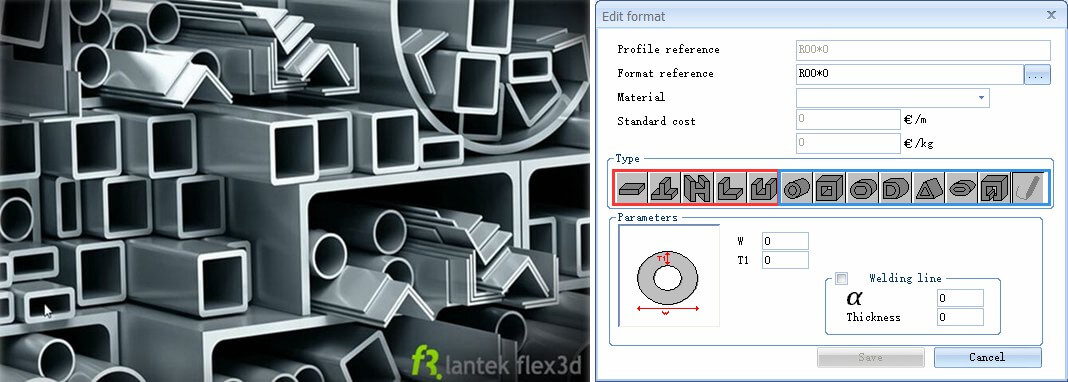

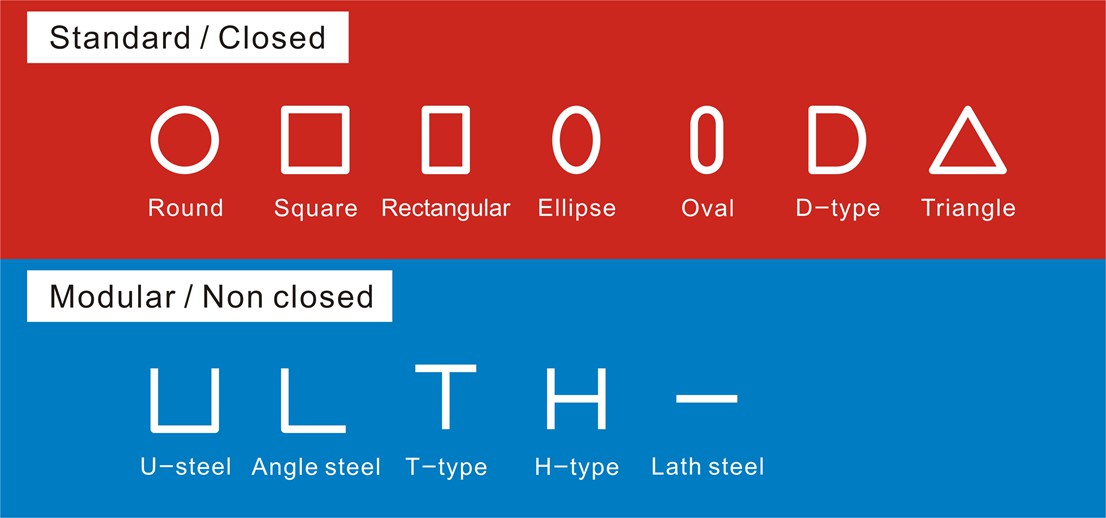

Lantek Flex3d supports a variety of pipe types

- • Standard tube type: Round tube, square tube, OB-type tube, D-type tube, triangle tube, oval tube, etc. And special-shaped pipe of equal diameter.

- • At the same time, flex3d has functional modules for profile cutting, which can cut angle steel, channel steel and H-shaped steel, etc.

Technical Specifications of the Laser Tube Cutting Machine

| Model |

P2060 / P3080 / P30120 |

| Tube length |

6000mm / 8000mm / 12000mm |

| Tube diameter |

20mm~200mm / 20mm~300mm |

| Laser source |

IPG / nLight fiber laser resonator |

| Laser power |

700W / 1000W / 1500W / 2000W / 2500W / 3000W / 4000W / 6000W |

| Laser head |

Raytools, Precitec ProCutter |

| Maximum rotate speed |

120r/min |

| Repeat positioning accuracy |

±0.03mm |

| Maximum positioning speed |

90m/min |

| Acceleration |

1.5g |

| Cutting speed |

Depend on materials, laser source power |

| Electric power supply |

AC380V 50/60Hz |

Applications of the Tube Cutting Laser Machine

Applicable material

Specially for cutting metal tubes such as round tube, square tube, rectangular tube, oval tube, waist tube, triangle pipe, channel steel, angle steel, U-bar, T-type, I-beam, lath steel, etc.

Applicable Industry

Furniture, medical device, fitness equipment, display rack, automobile industry, agriculture and forestry machinery, fire pipelines, steel frame structures, oil exploration, bridges, ships, structure components, etc.