Features of the Laser Cutter Machine

Technical Specifications of the Cutting Laser Machine

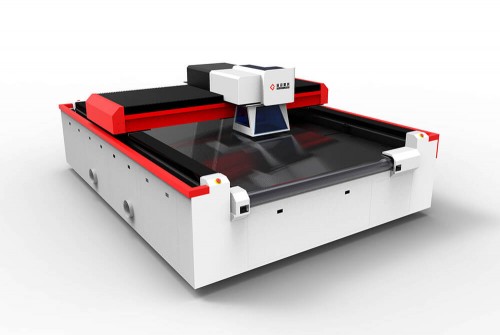

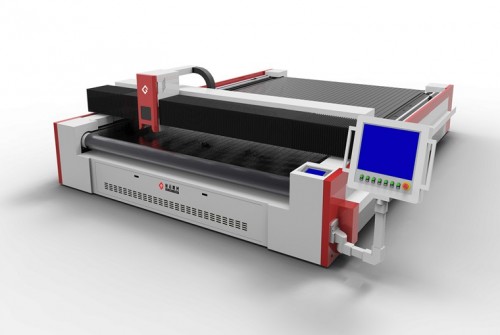

| Model No. | ZDJG-3020LD |

| Laser Type | CO2 glass laser tube |

| Laser Power | 65W / 80W / 110W / 130W / 150W |

| Working Area | 300mm×200mm |

| Working Table | Conveyor working table |

| Motion System | Step motor |

| Cooling System | Constant temperature water chiller system |

| Exhaust System | 550W or 1100W Exhaust system |

| Air Blowing | Mini air compressor |

| Working Accuracy | ±0.1mm |

| Power Supply | AC220V±5% 50/60Hz |

| Graphic Format Supported | PLT, DXF, AI, BMP, DST |

| Dimensions | 1760mm×740mm×1390mm |

| Net Weight | 205KG |

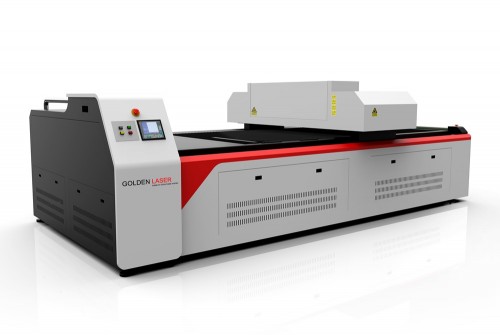

Applications of the Laser Cutting Machine

Material that can be processed by ZDJG-3020LD

Woven labels, embroidered labels, printed labels, webbing, ribbon, Velcro and other material on rolls.

Natural and synthetic fabrics, paper, leather, fiberglass, polyester, etc.